Overview

Date: July 2015

Client: N/A

Industry: Mining

ICS Industries was engaged to design, engineer and manufacture a passively-cooled solution for rail signal and Communication Cabinets for remote Western Australia. Each cabinet was required to accommodate racking and shelves to support 850 kg per rack; totalling 4,250 kg per cabinet.

They were also designed to effectively manage equipment heat load, reduce power consumption and protect equipment from dust and water ingress. The cabinets were delivered to remote locations for the new iron ore project in Pilbara, Western Australia.

Features

The cabinets incorporated several unique features to cater for the client’s specifications and environmental demands of a remote location; including water, dust and vermin proofing, and built to withstand the cyclonic nature of the area.

The cabinets were designed with integrated dual skin sandwich panels for venting and insulation as well as dual front and back doors, allowing complete ease of access. They were also designed to utilise passive cooling as the primary method of maintaining the internal temperature below a specified 60°C on a 50°C day (maximum heat load of 850 Watts).

The cabinets are solar and battery powered thereby minimising maintenance of the cabinets as well as eliminating the need for AC power. However, to combat the high heat load, a fan was included to ensure that even under the most extreme conditions, the client’s requirements would be met.

Notable features of the cabinets include:

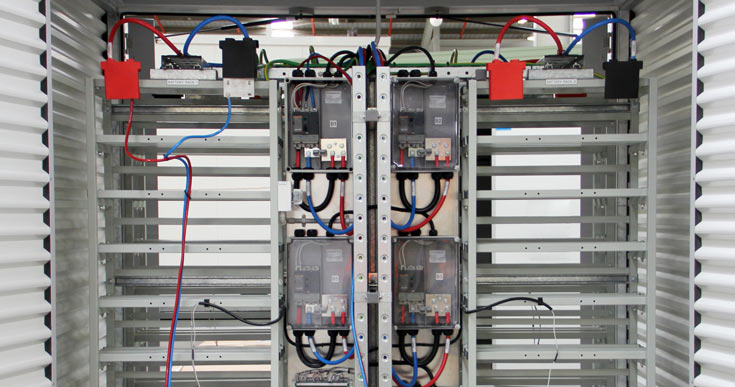

- Integrates various specialist equipment including communications, signalling, control gear and batteries.

- Passive cooling reduces power consumption; as it involves no active equipment.

- Sealed internal environment; protecting against dust and water ingress.

- Suited to remote locations; no need for mains power as they are exclusively solar and battery operated.

Outcome

The project saw the roll out of 24 Passive Cooled Battery Cabinets as well as six large shelters, all with high-end fit-outs, to form a key part of Western Australia’s rail network. All cabinets and shelters were designed and manufactured in accordance with the stringent requirements for documentation, inspection and test plan require by the client.